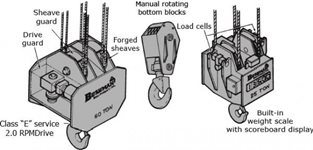

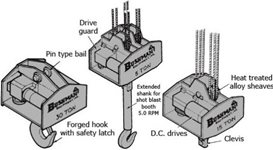

Bottom Blocks

Bushman AvonTec bottom blocks or hook blocks are designed for customers' specific applications. Sheave configuration, capacity, special control requirements and unique reeving patterns can be incorporated to improve crane operation. The motor-driven 360° rotating hook permits the crane operator to position heavy or awkward loads in less accessible work areas. Standard non-motorised bottom blocks are available for retrofitting or modernisation projects. They can also be manufactured in larger quantities for new crane installations.

All Bushman AvonTec bottom blocks are designed and manufactured in accordance with CMAA and AISE specifications and the latest revision of ASME Spec. B30.20 and BTH-1: Design of Below-the-Hook Lifting Devices.

Bottom Blocks are Available in the Following Crane Service Classifications:

-

Standby or infrequent use

-

Light service: Up to 5 lifts per hour at 50% of capacity

-

Moderate service: Up to 10 lifts per hour at 50% of capacity

-

Heavy duty service: High speed up to 20 lifts per hour at 65% of capacity

-

Severe service: High speed over 20 lifts per hour at 100% capacity

-

Continuous severe service: Production critical, continuous service at 100% capacity

STANDARD FEATURES

|

-

Machined steel sheaves

-

Welded steel construction

-

Tapered or straight roller bearings for smooth rotation

-

Adjustable slip clutch for Impact protection

-

Forged hook with safety latch

-

Lubrication fittings for hook and sheave bearings

|

OPTIONAL FEATURES

|

-

Mechanical rotation stops

-

Electrical limit switch -otation control

-

Motor controls: AC or DC, single speed magnetic or VFD

-

Remote controls

-

Collector rings for power below the hook

-

Solid state soft start

-

Built-in weigh scale with integral or remote display

-

Air motor rotation

-

Clevis in place of hook

-

Multiple sheave configurations

-

Pin-type ball connection

-

Hardened sheaves

|

Click on the images below to view examples of Custom-Designed Bottom Blocks.