Blade Systems

Blade Systems utilise a narrow slot to distribute the electrostatically-charged coating uniformly over the entire target surface. Blade Systems incorporate design features such as sharp edge technology, adjustable spray widths, and a heated delivery system. The patented L.A. Strip increases the density of the atomized particles within the charged pattern significantly more than conventional blade types. This enables L.A. Blade Systems to use less coating fluid and to operate over a wider range of coating weights.

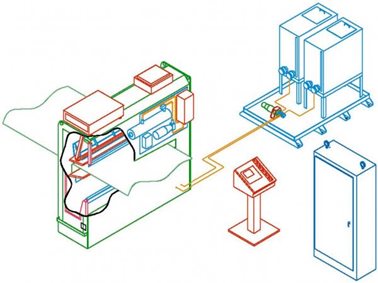

A Typical Peabody Blade Coating System

-

Solid State High voltage power supplies mounted on the cabin to minimise the

length of the connecting cable.

-

Linear Accelerator (L.A.) blades giving optimum atomlzation of oil under all

operating conditions.

-

Non conductive blade supports.

-

Telescopic blade mounts top and bottom to allow blades to be completely

withdrawn from the cabin for cleaning or maintenance.

-

Movable drip trough for overhead blade to prevent oil falling onto the strip during

line stop conditions.

-

"Table" type protection to protect blades from movement In the strip, particularly

during threading operations.

-

Dedicated blade heating to ensure oil in the blade is always at the optimum

temperature for atomization, even when line is stopped and no oil Is flowing.

-

Strong steel cabin ruggedly constructed in 12 mm thick plate.

-

Full length maintenance doors at both ends of the cabin with safety security locks

and gutters to ensure oil is kept inside the cabin.

-

Oil storage tanks, heated where necessary, with automatic oil changeover control

for multi oil types.

-

Precision metering pumps with servo motors to precisely meter oil to each blade.

-

Operators Interface (MMI) with all necessary control and alarm functions (remote

mounted where required).

-

Main electrical enclosure housing PLC (Programmable Logic Controller), Servo Motor

controllers, all relays, transformers, and overload circuits. Cabin available to a

variety of different standards including DIN.